2025/12/09

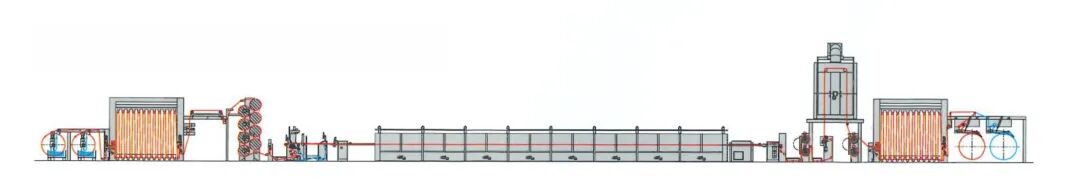

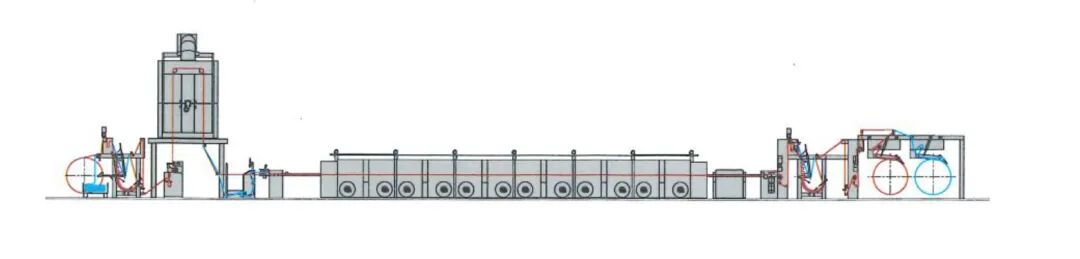

在10月ITMA ASIA + CITME新加坡纺织机械展览会上,恒天立信旗下品牌——德国门富士(Monforts),创新性地推出VertiDry垂直烘干机,该款新型设备凭借诸多卓越性能,为染整行业后整理环节带来了全新解决方案。

点击图片,揭密VertiDry芳容

Click on the picture to check VertiDry

At the forthcoming ITMA ASIA + CITME textile machinery exhibition in Singapore this October, the brand under CHTC Fong’s - Monforts innovatively launched the VertiDry vertical dryer. This new type of equipment, with its numerous outstanding features, brings a brand-new solution to the finishing process in the dyeing and finishing industry.

01

Diversified adaptability,

meeting the demands of diverse and high-quality production.

VertiDry 垂直烘干机具备强大的兼容性与适应性,能与德国门富士涂层机、EcoApplicator 布面加液机等设备完美结合使用,还能与定形机配合,发挥出更出色的效果。无论是新建染整产线,还是融入现存后整理产线,它都能轻松胜任,一个单元可容纳近8米织物,可极大地配合不同规模和类型的后整理生产线。

应用案例

Application Examples

安全气囊后整理工艺 -- 配合涂层机

Airbag Finishing with Coating

牛仔后整理工艺 -- 配合EcoApplicator

Denim Finishing with EcoApplicator

牛仔油光处理 -- 配合轧车

Denim Oiling and Waxing with Padder

The VertiDry vertical dryer features strong compatibility and adaptability. It can be perfectly combined with equipment such as Monforts coating machines or EcoApplicator units, and can also be used in conjunction with stenter frame machines to achieve even more outstanding results. The VertiDry can be integrated into both new and existing finishing lines. A single unit can accommodate approximately eight metres of fabric at any given time and multi-storey versions are also possible. This makes it very adaptable to finishing line configurations.

VertiDry采用无接触式对流垂直烘干技术,可助力织物最大程度实现柔软、柔顺等特性,为不同类型的织物带来高品质的烘干效果。该烘干机具备强大的适应性,能够满足不同类型织物在各个后整理流程中的多样化需求:在敏感织物的预干燥流程中,其独特设计能避免织物受损,保证后续加工质量;在安全气囊、牛仔布和玻璃纤维基材的涂层后流程,可确保涂层均匀且快速干燥,提升产品性能;在运动服、外套、地毯、土工布和防水油布的后整理流程,能赋予产品理想的外观和品质,满足不同纺织品的多样化需求。

VertiDry adopts contactless convection vertical drying technology, which can help fabrics achieve the maximum softness and smoothness, and bring high-quality drying effects to different types of fabrics. This dryer has strong adaptability and can meet the diverse needs of different types of fabrics in various finishing processes: in the pre-drying process of sensitive fabrics, its unique design can prevent fabric damage and ensure the quality of subsequent processing. The post-coating process for airbags, denim and fiberglass substrates ensures uniform coating and rapid drying, enhancing product performance. In the finishing process of sportswear, coats, carpets, geotextiles and tarpaulins, the ideal appearance and quality can be endowed to the products, meeting the diverse demands of different textiles.

02

Energy-saving and highly efficient, reducing production costs.

在可持续发展的时代潮流中,VertiDry垂直烘干机的节能特性尤为突出。它具备能量可循环利用功能,可利用的热源都能为其提供动力,并且可以根据工厂最经济的路线组合热源,实现能源的最大化利用。此外,该烘干机配备的集成排气管道可连接至热回收系统,如德国门富士的Energy Tower,进一步回收利用余热,大大节约了能耗,降低了生产成本,符合纺织行业可持续发展的趋势。

In the trend of sustainable development, the energy-saving features of VertiDry vertical dryers stand out particularly. It has the function of energy recycling. VertiDry can be powered by all available heating sources, or combinations of heating sources depending on the most economic route for the individual mill to achieve the maximum utilization of energy. In addition, The unit is further equipped with an integrated exhaust air duct and can also be connected to a heat recovery system such as the Monforts Energy Tower, to further recover and utilize the waste heat, greatly saving energy consumption and reducing production costs, which is in line with the sustainable development trend of the textile industry.

03

Easy installation, enhancing production efficiency.

设备适配不同类型的喷嘴,且喷嘴支持预设置,这一设计大大缩短了安装时间,从而提高生产效率,为企业创造更多的经济效益。

Different nozzle types are available for the unit which will be supplied pre-erected for shortest installation times, thereby enhancing production efficiency and creating more economic benefits for enterprises.

德国门富士VertiDry垂直烘干机的推出,不仅是后整理领域的一项工艺革新,更是面向未来制造的一次重要迈进。它以垂直设计突破空间限制,以智能适配实现广泛兼容,更以循环节能理念回应全球绿色制造的呼声。随着该项技术在全球范围内的推广与应用,德国门富士正引领行业步入高效、灵活、环保的后整理新世界,赋能染整行业迈向更智能、更绿色的未来。

The launch of the VertiDry vertical dryer from Monforts is not only a technological innovation in the finishing field but also an important step forward for future manufacturing. It breaks through spatial limitations with vertical design, achieves wide compatibility through intelligent adaptation, and responds to the global call for green manufacturing with the concept of circular energy conservation. With the global promotion and application of this technology, Monforts is leading the industry into a new world of efficient, flexible and environmentally friendly finishing, empowering the dyeing and finishing industry to move towards a smarter and greener future.